Plant Conveyors And Systems - Questions

Table of ContentsThe 15-Second Trick For Plant Conveyors And SystemsHow Plant Conveyors And Systems can Save You Time, Stress, and Money.Plant Conveyors And Systems Can Be Fun For AnyoneThe Single Strategy To Use For Plant Conveyors And SystemsMore About Plant Conveyors And Systems

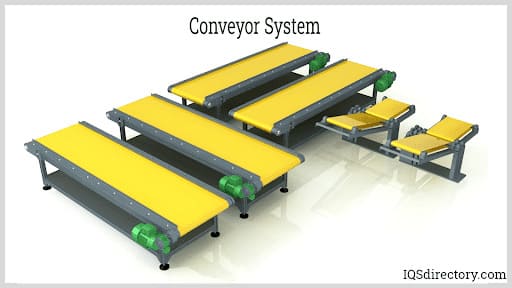

Below are 20 typical types of conveyors. This is possibly what you envision when you believe of a conveyor.It is built at a minor decline so parts slide downward by themselves. This resembles a gravity roller conveyor other than a chain or belt is utilized to make the rollers turn on their own, so they do not have actually to be developed on a decrease. In some cases they can even rise.

Bucket conveyor systems are made use of to move product up and down, by scooping it with a collection of pails affixed to a belt, chain, or wire. The conveyor moves the buckets upward, scooping up the product, and bring it to the top before dumping it out. explains this type of conveyor system: "Ball Transfer tables or conveyors make use of a collection of installed round wheels to permit unpowered, multi-directional transportation of the product." Basically, picture rows of steel rounds on a table that can turn and turn in any kind of instructions.

The Main Principles Of Plant Conveyors And Systems

Instead of having rollers or a belt, they have relocating chains to lug items. There is a whole family of conveyors that lug their tons under them rather of on top of them.

Other times they are mechanized. Often, just like the Power-and-Free Conveyor, they have 2 tracksone mechanized and one not motorized. Transform a cart conveyor upside down, affix it to the floor rather of the ceiling, as well as you've got an upside down monorail. This rail lugs product from below. Thomasnet. com states: "Magnetic Conveyors use moving magnets installed beneath fixed plates, tables, or other kinds of non-magnetic slider beds, to move magnetic (ferrous) products, frequently in the type of machining scrap." This conveyor shakes a little to relocate mass material along it.

The Ultimate Guide To Plant Conveyors And Systems

There are additionally various other relevant tools that make use of a chain to drag things such as a tubular drag conveyor. These conveyors make use of a vacuum cleaner or air pressure to move material.

These are comparable to a roller conveyor other than with small, specific wheels instead of long, round rollers. Walking Light beam conveyors relocate material incrementally along the conveyor making use of relocating as well as fixed supports.

If you require aid picking a conveyor system, allow us know. We have over 35 years of experience dealing with tasks big (up to $30 million) and also little.

The Facts About Plant Conveyors And Systems Revealed

Introduction The total guide to conveyor systems on the internet. You will discover: What is a Conveying System? Conveyor System Requirements Kinds Of Conveyor Solutions How Does a Conveyor System Job? And a lot more Phase One What is a Conveyor System? A conveyor system is a method for relocating bundles, products, products, parts, and equipment for manufacturing, delivery, or moving.

Tons Capability: Once the More Bonuses system has been laid out and offered a pattern, it has actually to be established what will certainly be the amount of products it can carry - Plant Conveyors and Systems. Straining a he has a good point system can damage it or trigger it to stop in the midst of its procedure. Variables that influence the tons capacity are general size and bed width as well as the drive system.

The Best Strategy To Use For Plant Conveyors And Systems

Activity of powdered, granular, and chip kind materials can have dust develop, which is thought about in system design and may demand some type of purification. As with various other communicating systems, a careful examination of the characteristics of the product is required. Configuration: Sharing systems can be found in a wide range of forms, designs, dimensions, and also forms.

Since each system is made to fit an unique application, it would be impossible to cover all of the different next setups. What is vital to comprehend is that there are very couple of limitations on adding a conveying system, despite the application. Drive System: The drive of an automated communicating system is the power that relocates products.